-

19

94FOUNDATION OF LEKOS AND FIRST BEGINNINGS

Ing. František Ledl founded

the company Lekos s.r.o. TrebišovComplex technology for chocolate and glaze storing and devices for chocolate tempering are the first machines to be produced by the Lekos brand.

-

19

95LEKOS IN rented

WORKSHOPCherry dispenser for batching sour cherries into moulds on chocolate moulding line.

-

19

96Cooking equipment for sugar-syrup solution with a capacity of 6 tonnes per hour with automatic weighing and dosing of ingredients and with a distribution of mixture for several production lines all controlled by computer.

-

COMPANY’S DEVELOPMENT

Lekos moves to its own premises with a production area of 600 m2 in the town of Trebisov. Later on the company will expand the producing capacity with a second production hall of 600 m2 in Vojcice.

-

19

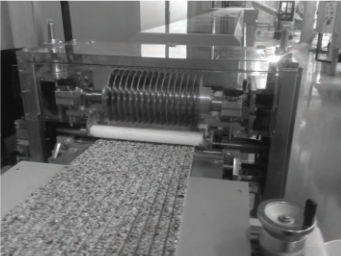

97The first complete production line for the production of cereal bars including a kitchen.

-

The first complete enrobing line Lekos.

-

19

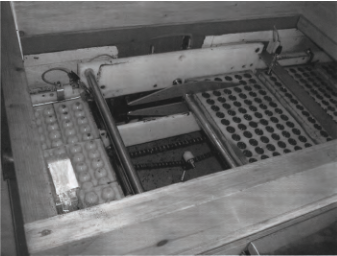

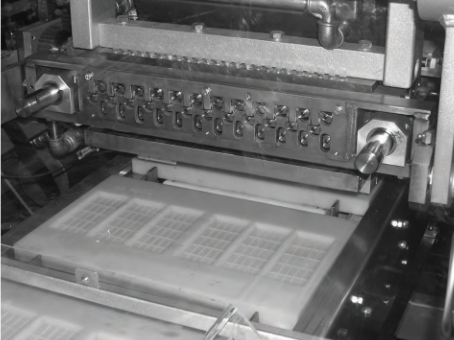

99Gradual reconstructions of chocolate moulding lines and new stations for existing chocolate moulding lines.

-

20

03The first complete moulding line from Lekos producing chocolate bars with a maximum capacity of 700 kg per hour.

-

20

06CENTRALIZATION OF PRODUCTION AND FURTHER COMPANY DEVELOPMENT

Lekos centralizes production in a new manufacturing plant with a production area of 3000 m2 in the town of Secovce.

-

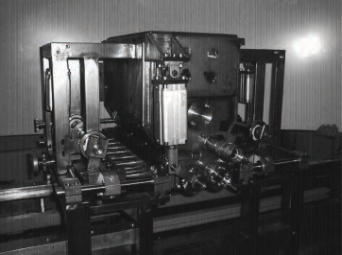

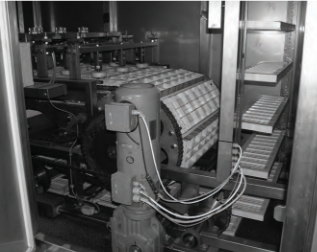

The first complete chocolate forming line designed for production of plain chocolate bars, filled bars and pralines, including sea shells.

-

20

09Within 14 months Lekos produces 3 operating forming lines with a total production capacity of 8,5 tonnes per hour. The lines are essentially producing a wide range of chocolates bars and pralines.

-

20

10Investments into a laboratory to create our own bar line with a complete enrobing part and additional devices for the extension of our customer service.

-

20

11Extension of the manufacturing area with a new production hall covering our current 4000 m2.

-

since

20

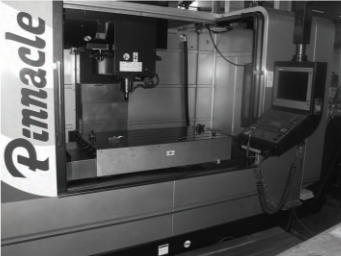

06Extensive investments into modern vertical and horizontal CNC drilling and milling machines.

-

since

20

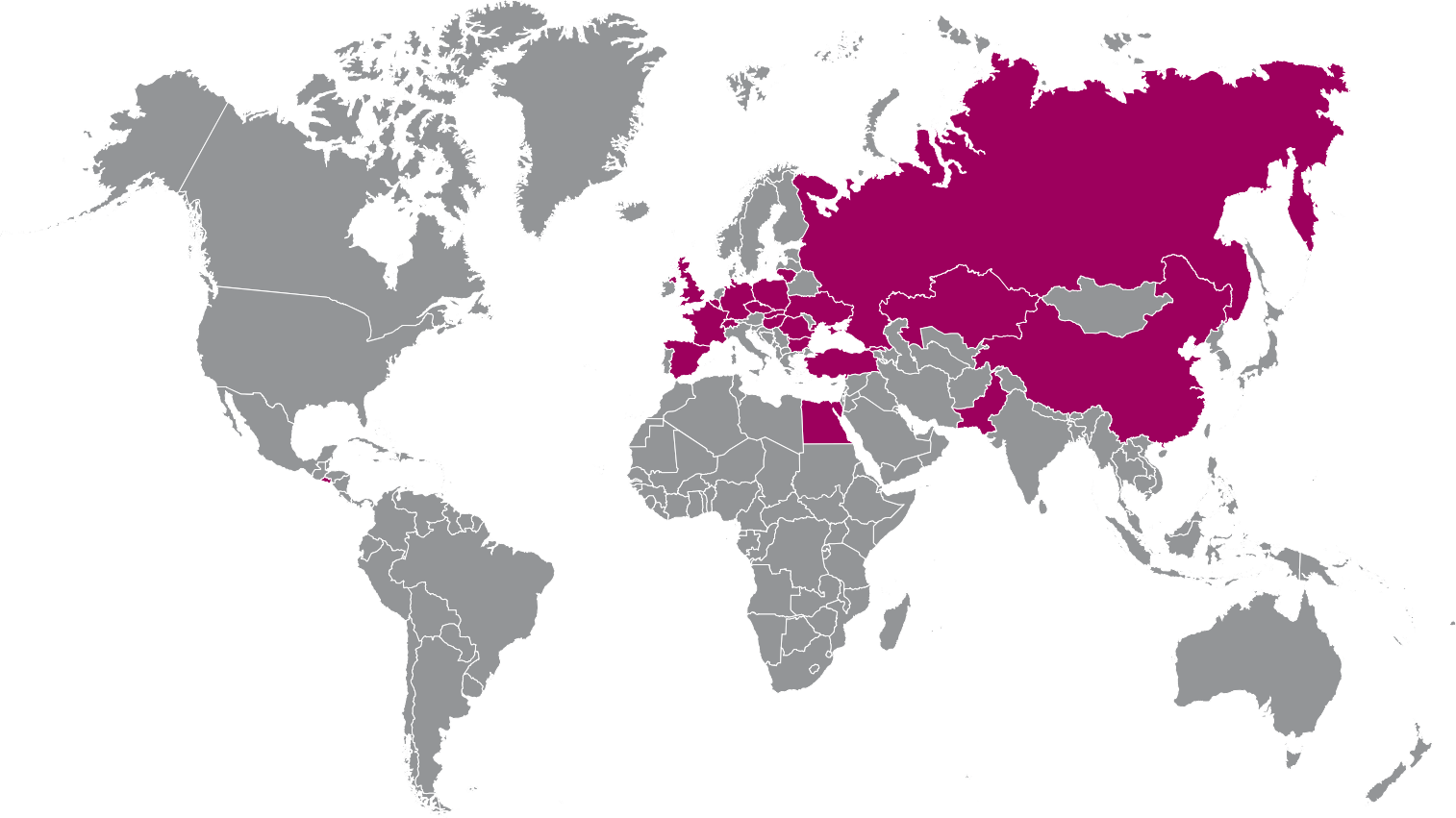

10LEKOS STRENGTHENS ITS POSITION AMONG TRADITIONAL CLIENTS AND ENTERS NEW MARKETS

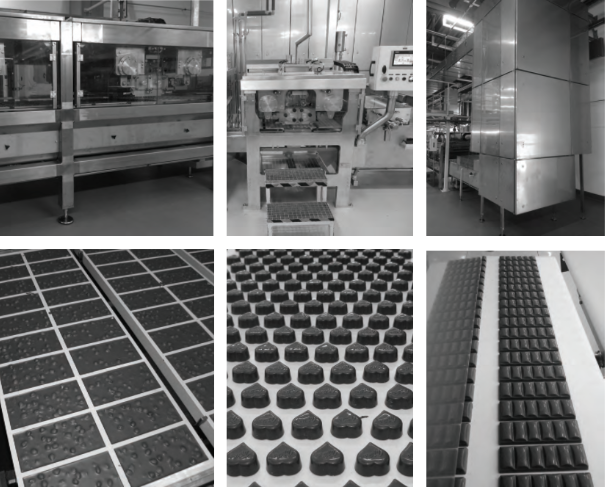

Extensive projects of new high-capacity moulding lines for productions of various chocolate moulded products, such as plain, filled including some very specific products. Such projects were realized for various customers mainly in Europe but also for many international companies with factories in Pakistan, Turkey and Egypt.

-

since

20

12Big projects of new bar lines dedicated for the production of cereal bars, oat bars, protein bars for sportsmen, but also French nougat and others. Many of these projects were realized as key-event projects including the kitchen, the bar production line, the enrobing line and packing line, including the design of recipes and the implementation of a new bar line technology.

-

since

20

16Lekos became a global supplier of a specific type of depositing system for important international company and during 2017 Lekos installed these depositors in chocolate factories all over Europe and China.

-

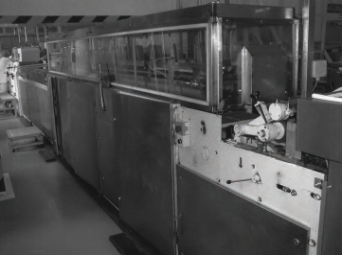

Development and first installations of a new chocolate enrober with redesigned principle for easy and fast change-over on production lines.

-

20

17Extensive investments in Lekos encouraging company

Growth, future development and improvement of customer serviceLekos opens a brand-new building dedicated to the continuous expansion of the technical team, PLC specialists, sales department, administration and others. It has enough space for further company growth and expansion.

-

20

18Lekos realises a big project thanks to its own new research and development centre in Secovce equipped with a new testing and production bar line. The production line and new testing centre will serve for presentation of new Lekos machines to our clients and also it will serve for testing and development of machines and new confectionery products. It is designed according to the rules and requirements for the production in the confectionery industry. It also features available space for the future expansion of a new testing chocolate forming line created by Lekos.

-

20

1925 year anniversary of Lekos