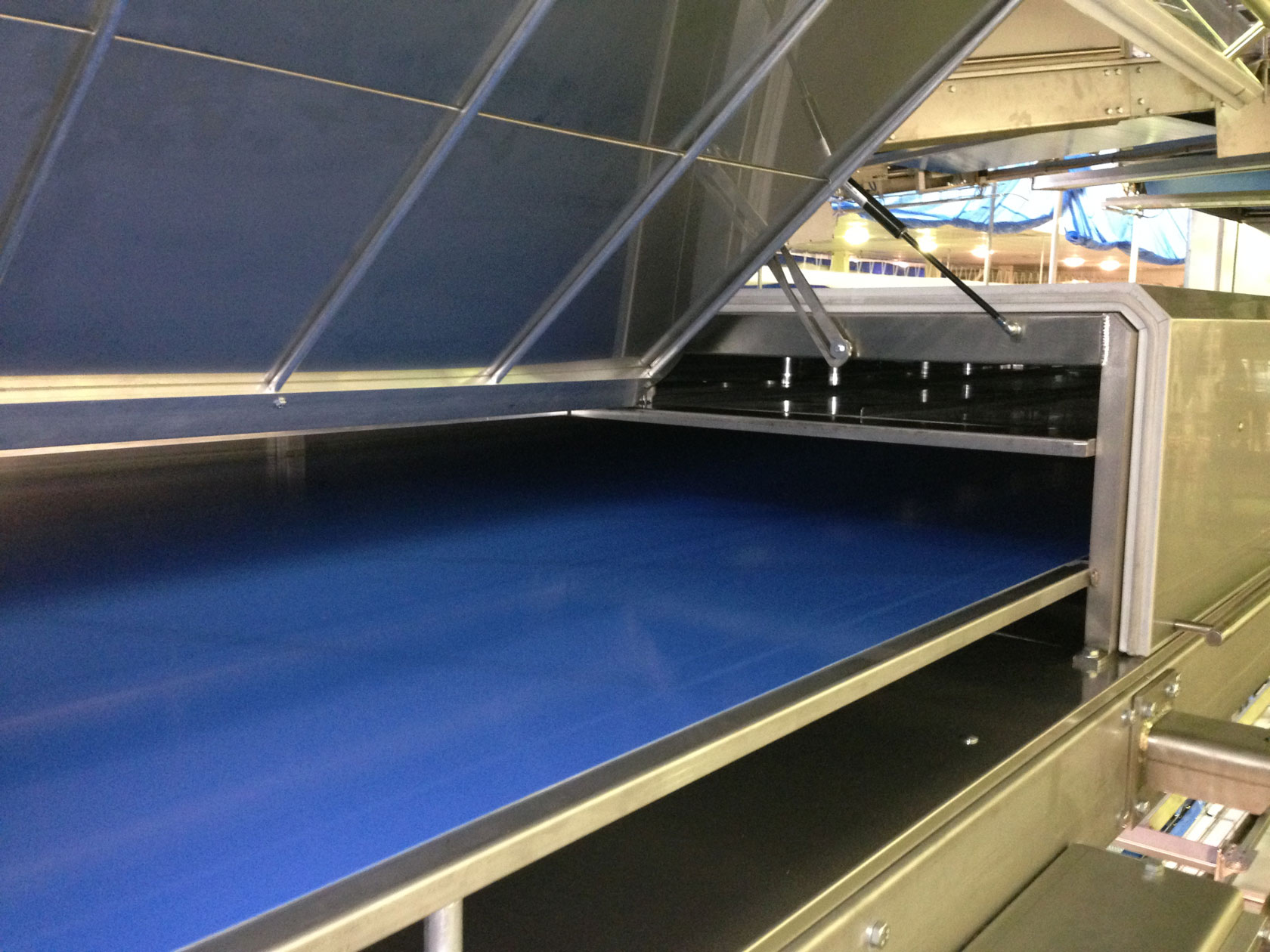

At Lekos you can find cooling tunnel of a high quality which is perfect for almost any application in confectionery and bakery. Most of cooling tunnels are equipped with polyurethane belts and are dedicated for cooling of various products on biscuit lines, bar lines, enrobing lines or chocolate drop lines.

Anyhow, key features of Lekos cooling tunnels are:

- Stainless steel execution

- Sufficient inside time which is always carefully calculated and additionally verified by experiences and by use of our R&D centre

- One or combination of more from following types of cooling - upper convectional cooling, upper radiation cooling, bottom cooling either by air or by cooling bed

- Overall length of cooling zone is split in several cooling sections, each of them has its own cooling box with separated way of control and settings in order to handle product properly in every application

Further key features are:

- Accessibility and cleanability

- Rollers, scrappers, sheets, catch trays and other components are easy to remove for cleaning

- Noses of the belt suitable for transfer of small products, fine and precise adjustability of their position

- Hygienic execution of doors and covers

Cooling tunnels with other than polyurethane belts are also available,e.g. tunnels with modular belts for cooling of moulds with chocolate for production of hollow figures.

Standard belt width is between 450 and 1500mm. We offer customized tunnels which we are able to fit for existing lines, too.