Forming section

Lekos twin-roller slab-forming unit has been continuously developed during last two decades based on experience from previous projects. Standard features of twin-roller slab-forming unit Lekos are:

- Own cooling and heating system, temperature of the roller adjustable usually between +5 and +60°C

- Cooling up to -12°C on the rollers for nougats

- Scrappers of both rollers are easily removable and exchangeable, scrapper design and material may differ based on nature of formed mass

- Lubrication of all rollers

- Removable hopper for easier cleaning

- Mass level control and many more....

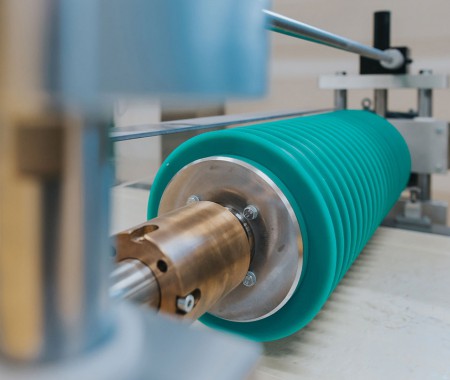

Following levelling roller is servo-driven, with its own cooling and heating system, scrapper and lubrification. Main features are:

- Own cooling and heating system, temperature of the rollers adjustable usually between +5 and +60°C, cooling to lower is also available

- Scrapper of the roller is easily removable

- Lubrication of the roller

- Robust construction

- Precise gap adjustment

- Even compression across the overall cross-section of the slab

Various assemblies of slab-forming and leveling units, nut or crisp rice sprinkling unit, forming and pre-cutting roller are available. The fact that we can make some of them as mobile units and these can be re-arranged differently in the forming section enable us to deliver line with high flexibility to our customers. Following are optional units: